Monozukuri is

Human Resource Development

Manufacturing

DNPS

The DaikyoNishikawa Production System (DNPS) is an activity that involves

all employees in thorough pursuit of value thereby realizing the ideas of

value formation and just on time at a high level and giving each production

staff member the ability to make profits. Based on the concept of just on

time, we increase value by standardizing all work in Monozukuri in terms of

both people and equipment, and we have realized model-mixed scheduled

sequential production1 centering on straight production.

In addition, DNPS activities set five targets: “safety and security,”

“environment,” “quality,” “delivery,” and “productivity.” We believe that

the process of pursuing these targets will greatly facilitate the growth of

each employee, enabling development of human resources embracing better

ideas. By acting while leveraging the way of thinking acquired through these

activities, we are realizing One Best Way.

1. Model-mixed scheduled sequential production: To produce various vehicle

models in an established order

Click here for details

Monozukuri

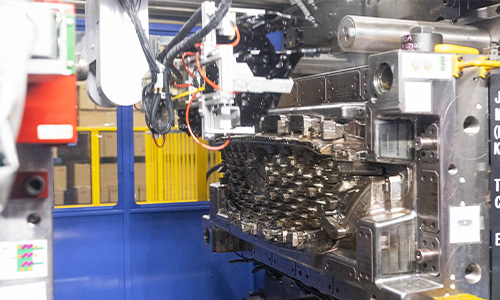

Molding

A heated plastic material is injected into molds of various shapes and

then cooled. In this way, plastic products of a wide variety of shapes

can be molded. Various molding techniques such as injection,

compression, blow, powder slush, and polyurethane injection are used to

pursue Monozukuri that meets customer needs and to conduct eco-friendly

manufacturing.

Click here for details

Painting

The painting process receives materials from the previous process—the

molding process—and increases the value of products by painting them,

achieving both quality and environmental requirements and meeting

diverse customer needs. We have realized unmanned painting equipment

using a spindle method tailored to automotive large parts, electrostatic

painting, and painting robots, which improve painting efficiency. We

also offer premium colors with high quality even though they are

difficult-to-achieve paint colors.

Click here for details

Assembly

Assembly is the worksite that is the closest to our customers.

Model-mixed scheduled sequential assembly is realized tailored to

customer requirements. The assembly process assembles more than 80 parts

at the most, by methods such as bolting,2 fitting,3

affixing, and insertion, to name a few. Our Monozukuri is safe and

efficient, combining human-friendly unmanned assembly, the introduction

of collaborative robots, development of processes with clear criteria

for work difficulty, and ergonomics4 evaluation. In addition,

to be in line with customer needs, we select a production system from

cell, lot, AGV (Automatic Guided Vehicle), and other production systems.

Our goal is to assemble and deliver products to our customers on a

just-on-time basis (delivering when and what is needed and in the

precise amount needed).

2. Bolting: to tighten with threaded fasteners

3. Fitting: to mate parts

4. Ergonomics: human engineering

Click here for details

Kaizen (Improvement)

To achieve the desired state in small groups, we note the difference

between the current state and the desired state (ideal model) of the

worksite and formulate strategies, identify problems, clarify issues,

and promote Kaizen activities to resolve the difference.

Click here for details